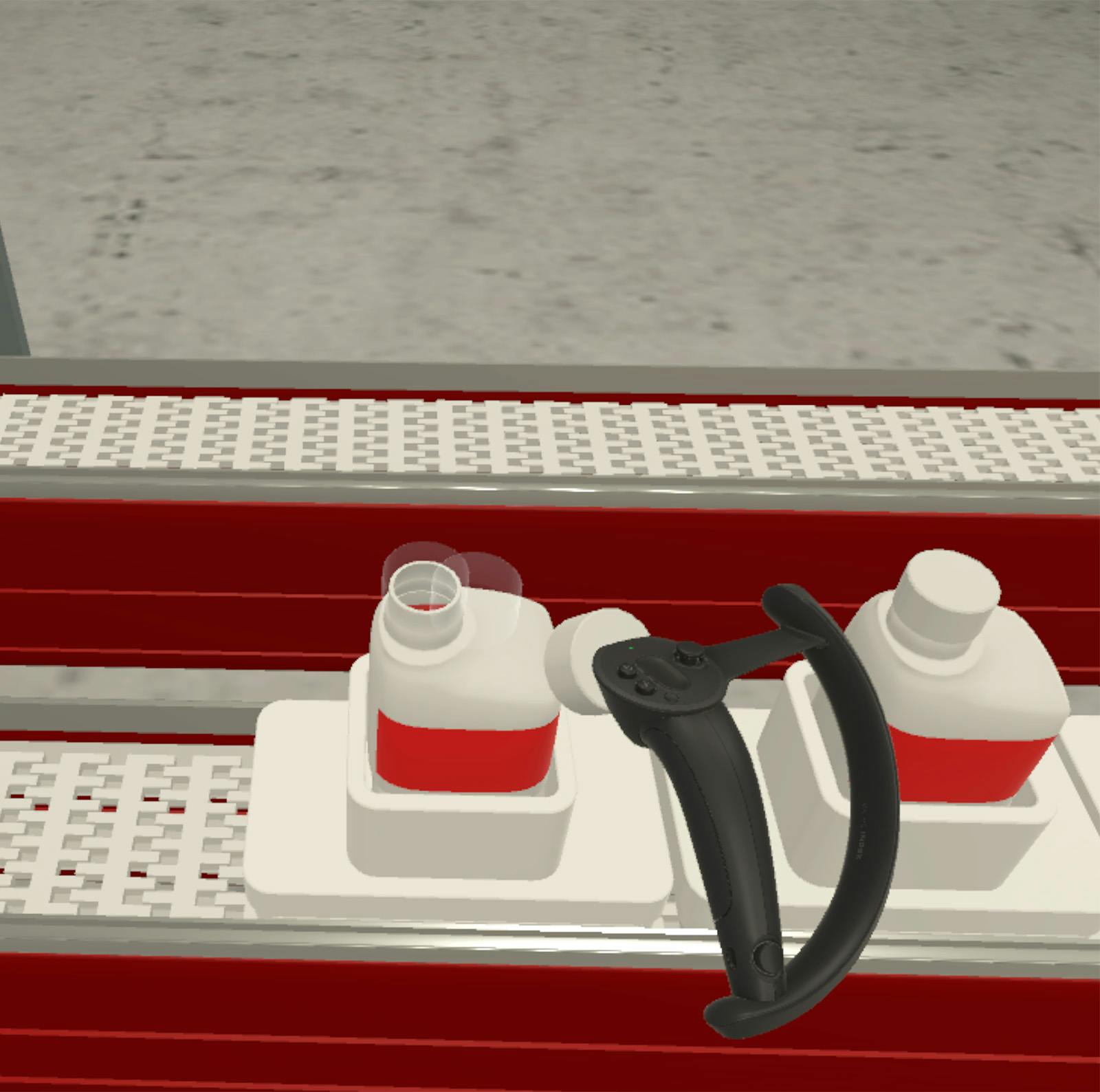

Conveyor belt quality control

Learn the right procedure virtually

With VR training no need for limiting or shutting down production

Enlarge the awareness of employees

Virtually working at a conveyor belt

The virtual reality training from Diversey reduces the loss of the production capacity and lowers the failure costs.

Virtual training for the conveyor belt

The international company Diversey, with approximately 11.000 employees, delivers revolutionary cleaning and hygiene techniques to their clients. They produce and develop cleaning products, sanitary products and maintenance products. They also offer systems and services where chemicals, machines and sustainable programs are efficiently integrated.

For one of the conveyor belts of Diversey we have developed a VR training. In this training bottles need to be filled, checked and labeled. A mistake made with the filling can have enormous consequences for the cleaning process of a client. It can lead to high costs and of course Diversey wants to avoid this. That is why this VR training has been developed and implemented.

Create awareness at the employees

Due to the virtual training of Diversey the employees at the conveyor belt do not only know the critical elements, but it also creates awareness at the employees. The training creates more awareness about the consequences of possible mistakes at the endproduct and even at the user of the endproduct.