Grinding machine preparation

Saving time as VR training is possible at any location all over the world

By training in VR the chances of making mistakes is much more reduced

Fewer mistakes = less failure costs

Reducing the CO2 footprint

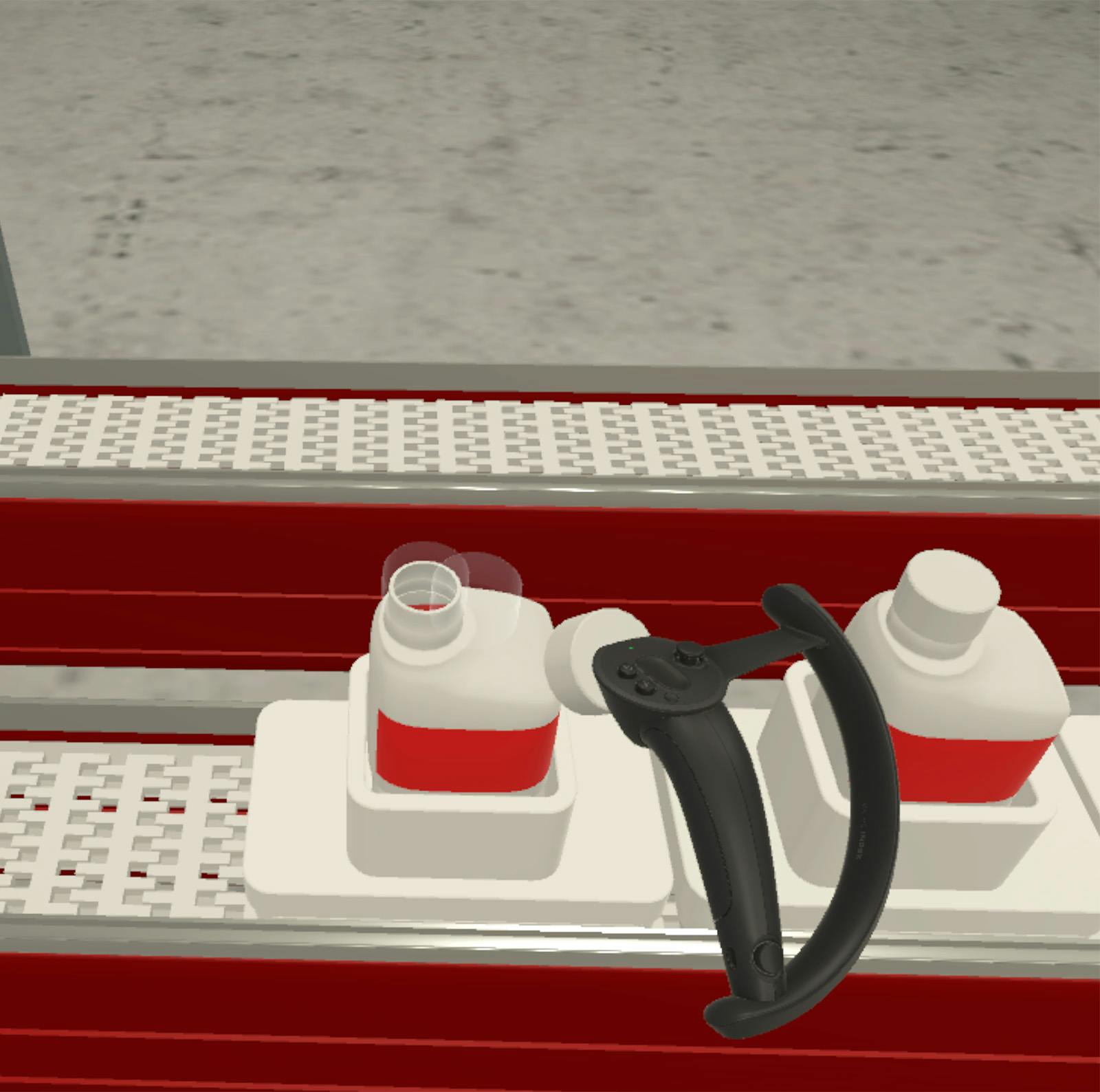

VR training for preparing a grinding machine

The VR training from Andritz Metals makes sure that everywhere in the world, it is possible to train safely for the preparation of a machine.

Virtual training to prevent damage

We have developed three different interactieve training applications for Andritz Metals. The clients of Andritz Metals have to be able to maintain their machines. This can be a very costly matter, because a certain part costs € 50.000,-. It can cause a lot of damage and costs when this part placed in the wrong way.

In three different training applications the trainee learns how to maintain the whole machine. Because the machine has different parts that need to be maintained, we have made three different training applications.

Learn quicker without travelling time

The virtual training applications developed for Andritz Metals do not only safe costs but also time. In the past clients had to come to Germany to be trained to work with these machines. For example in Mexico there is a lot of changes going on in the personnel. It happens very often that different employees have to work with the machine. With each change in personnel, training needs to be done again. With our solution training can be done safely in a virtual environment. The virtual training applications are made in multiple languages so they can be used worldwide.

A VR training does not only safe cost and time, but it also reduces the CO2 footprint of the company. It is possible to train at any location on the world and at any time when employees train in VR. The number of travel hours will be drastically reduced and this is a large benefit to the ecological footprint.